What are the selection criteria for branch pipes?

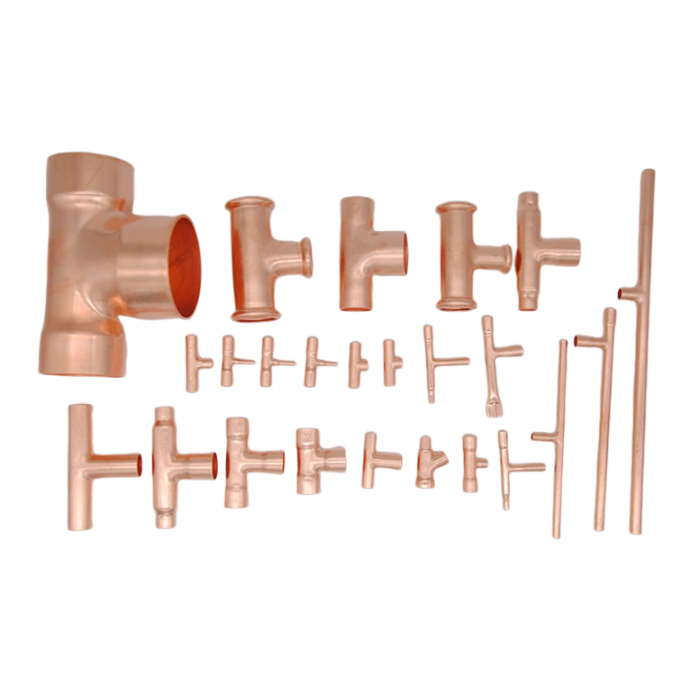

2024-08-14Branch pipes are made of copper pipes and welded together, so their selection is also very important. For example, R410A refrigerant is more environmentally friendly than traditional refrigerants, but its pressure is also greater than that of traditional refrigerants. If it is not properly selected, it may leak and burst after installation. It causes a lot of losses to the refrigeration system and causes unnecessary trouble.

1. Look at the material of the copper pipe: The quality of the copper pipe directly determines the quality of the branch pipe. Now the central air conditioner mainly uses R410A refrigerant, which has high pressure, and the branch pipe processing also needs to use R410A special copper pipe, which is thicker than ordinary copper pipes and has high pressure.

2. Look at the thickness of the branch pipe: the thicker the thickness, the greater the pressure, so when choosing a branch pipe, look at the thickness first.

3. Look at the welding place: The branch pipes are welded, and the welding place is also the most prone to problems. The main problems of welding are sand holes, desoldering, and internal oxides. A good branch pipe should have a clean pipe wall, no impurities, and no black spots.